Description

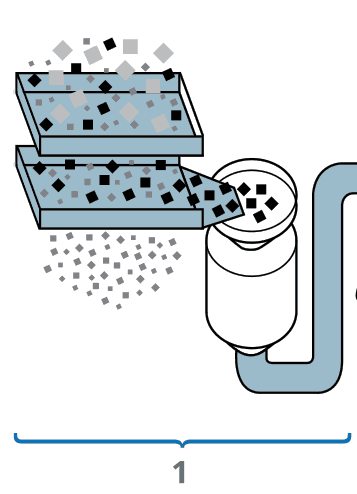

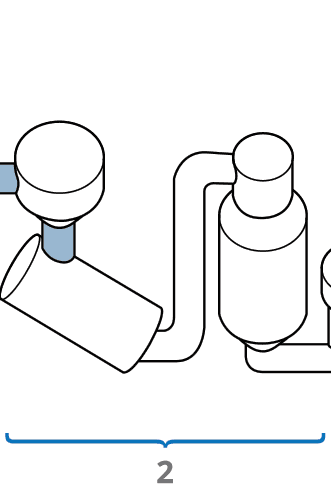

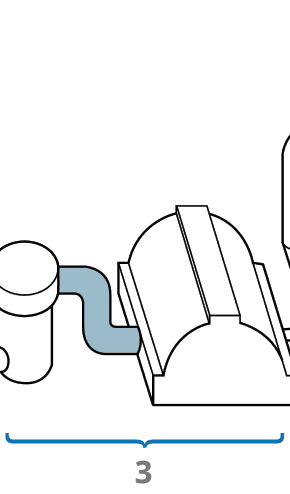

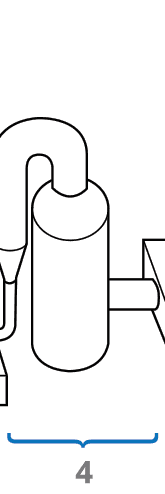

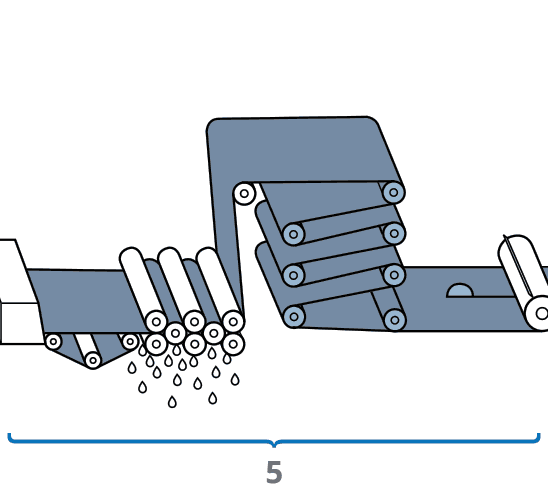

The essential elements for making kraft pulp are wood fibre, water, chemicals and heat. We make kraft pulp by mixing wood fibres with a solution of caustic soda and sodium sulphide, and cooking them inside a digester. This separates the fibres from the lignin, which is a natural glue-like substance that binds them together. Our production facilities are designed to recover and reuse much of the water, chemicals and steam used in the process.

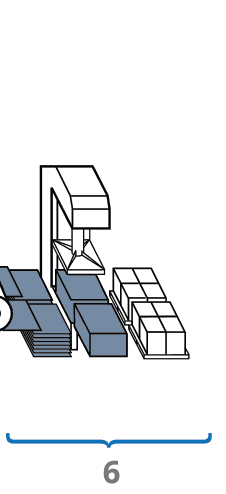

Packing

Bale

Size:

800х600х450 mm

Gross weight:

201 kg

Nett weight:

200 kg

Pack (6 bales)

Size:

800х1200х1350 mm

Gross weight:

1206 kg

Nett weight:

1200 kg

Characteristics

| UNIT | VALUES | BASED ON | |

|---|---|---|---|

| Reverence values of mechanical properties at 60°SR | |||

| Breaking length | km | Not less 7.8 | RF GOST 13525.1 |

| Breaking strength | number of double kinks | Not less 800 | RF GOST 13525.1 |

| Guaranteed values for optical properties | |||

| Brightness | % ISO | Not less 88 | RF GOST 7690 |

| Dirt Count | number of specks from 0.1 to 1 mm² | Not more 70 | RF GOST 14363.3 |

| number of specks from 1 to 2 mm² | Not more 2 | ||

| Fiber morphology and other characteristics | |||

| Wood | Spruse | ||

| Fiber length | mm | 2.34 | L&W Fiber Tester |

| pH | 5.5–7.0 | RF GOST 12523 | |

| Moisture content | % | Not more 20 | RF GOST 16932 |

Reviews

There are no reviews yet.